3DCP Watertaxi Stop

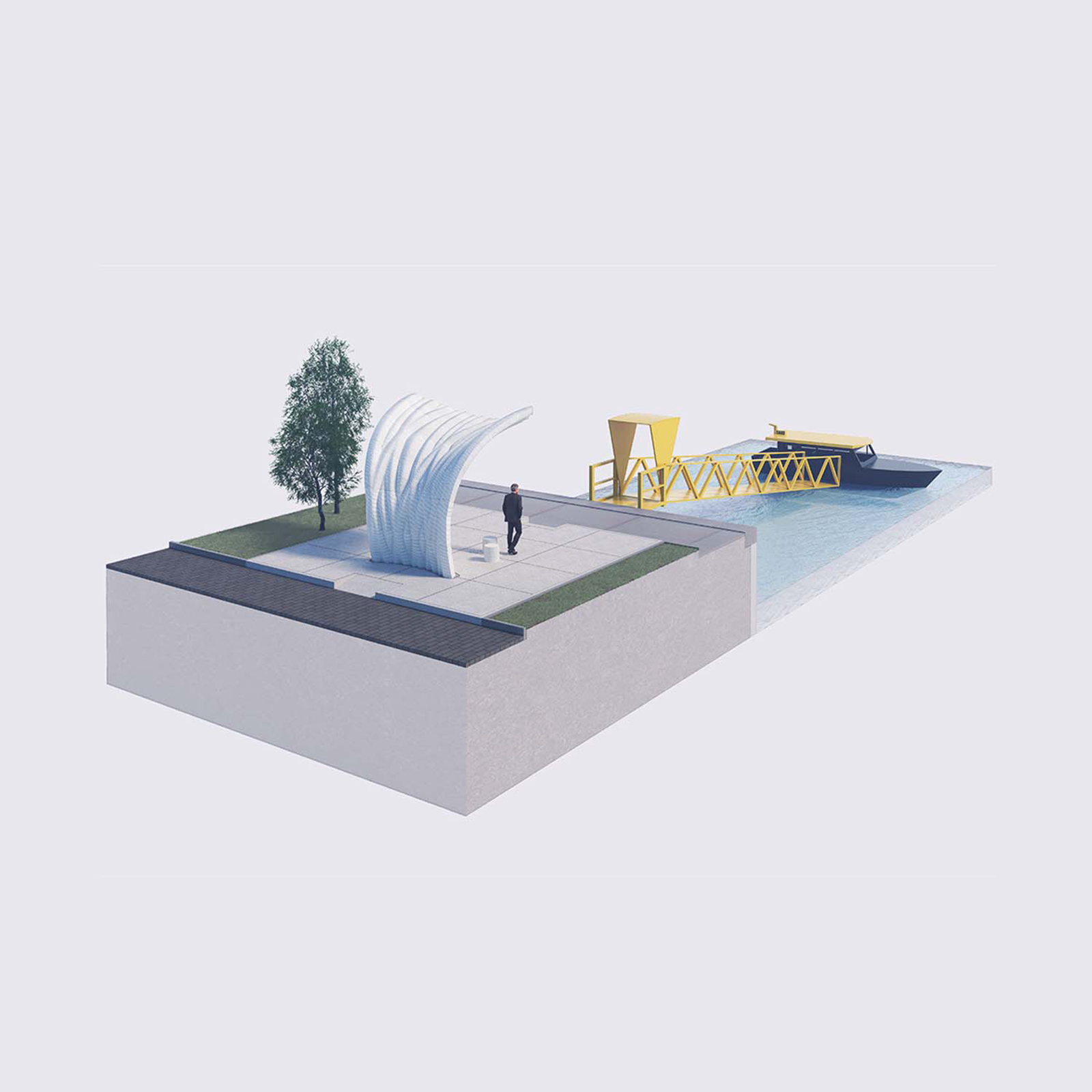

The city of Rotterdam is split by the river de Nieuwe Maas. A small fleet of watertaxi’s allow passengers to quickly travel between remote and central parts of the city while enjoying the impressive waterside view of the city. In contrast to those using regular public transport, watertaxi passengers are often waiting outside, exposed to rain and wind.

Client Municipality of Rotterdam

Location Rotterdam, NL

Engineering Studio RAP + Movares

3d-concrete-printing Bruil Prefab Printing, Eric Barendse

Structural design Movares

Material supplier Metsawood

Status In design

Client Municipality of Rotterdam

Location Rotterdam, NL

Engineering Studio RAP + Movares

3d-concrete-printing Bruil Prefab Printing, Eric Barendse

Structural design Movares

Material supplier Metsawood

Status In design

For this specific case, Studio RAP initiated a revolutionary design solution that takes into account the large variety of area’s the watertaxis serve. Studio RAP has developed a parametrically designed watertaxi stop for the City of Rotterdam that applies state-of-the-art concrete printing technology. The design of the abri emerges from specific functional requirements, innovative structural design and rapidly evolving 3D printing possibilities.

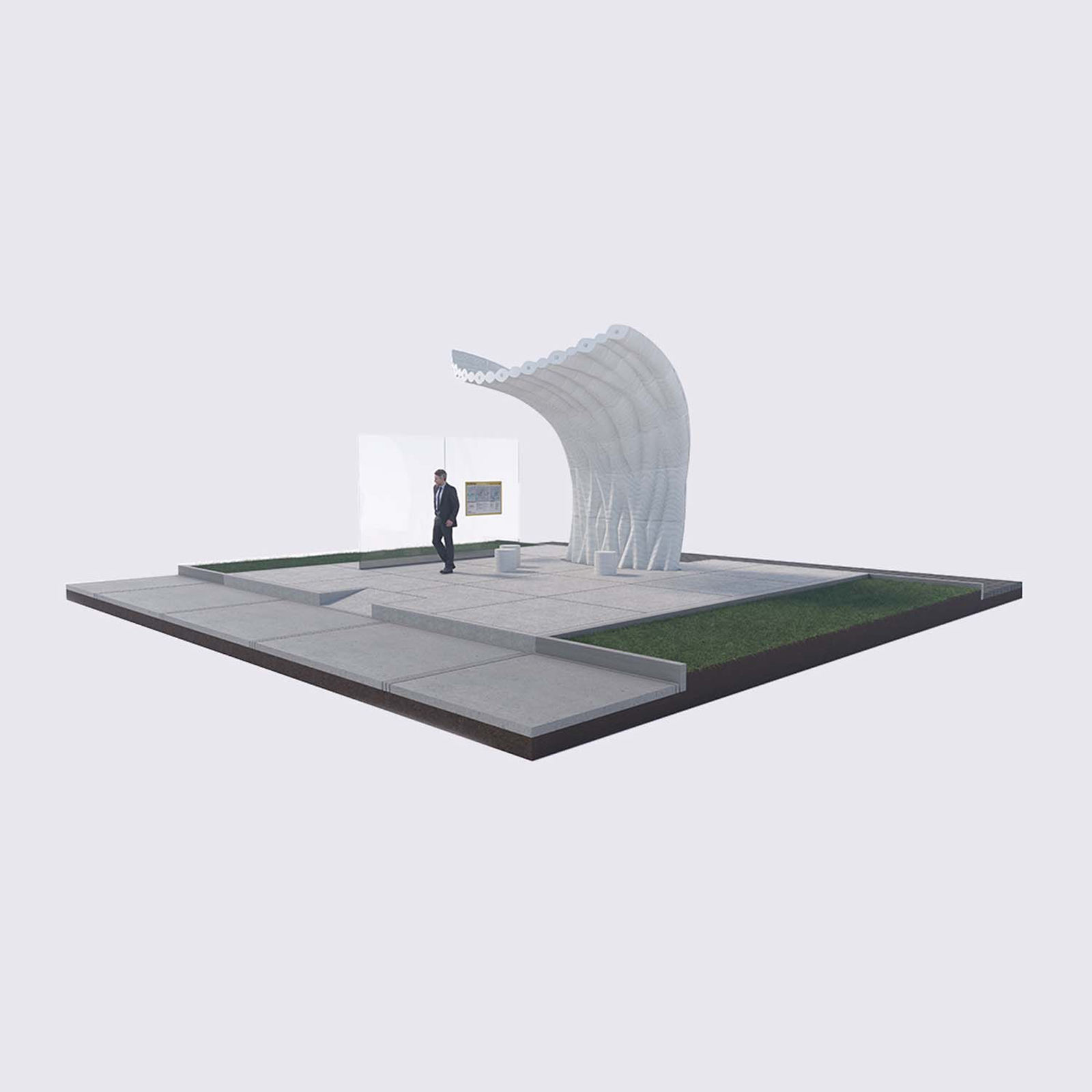

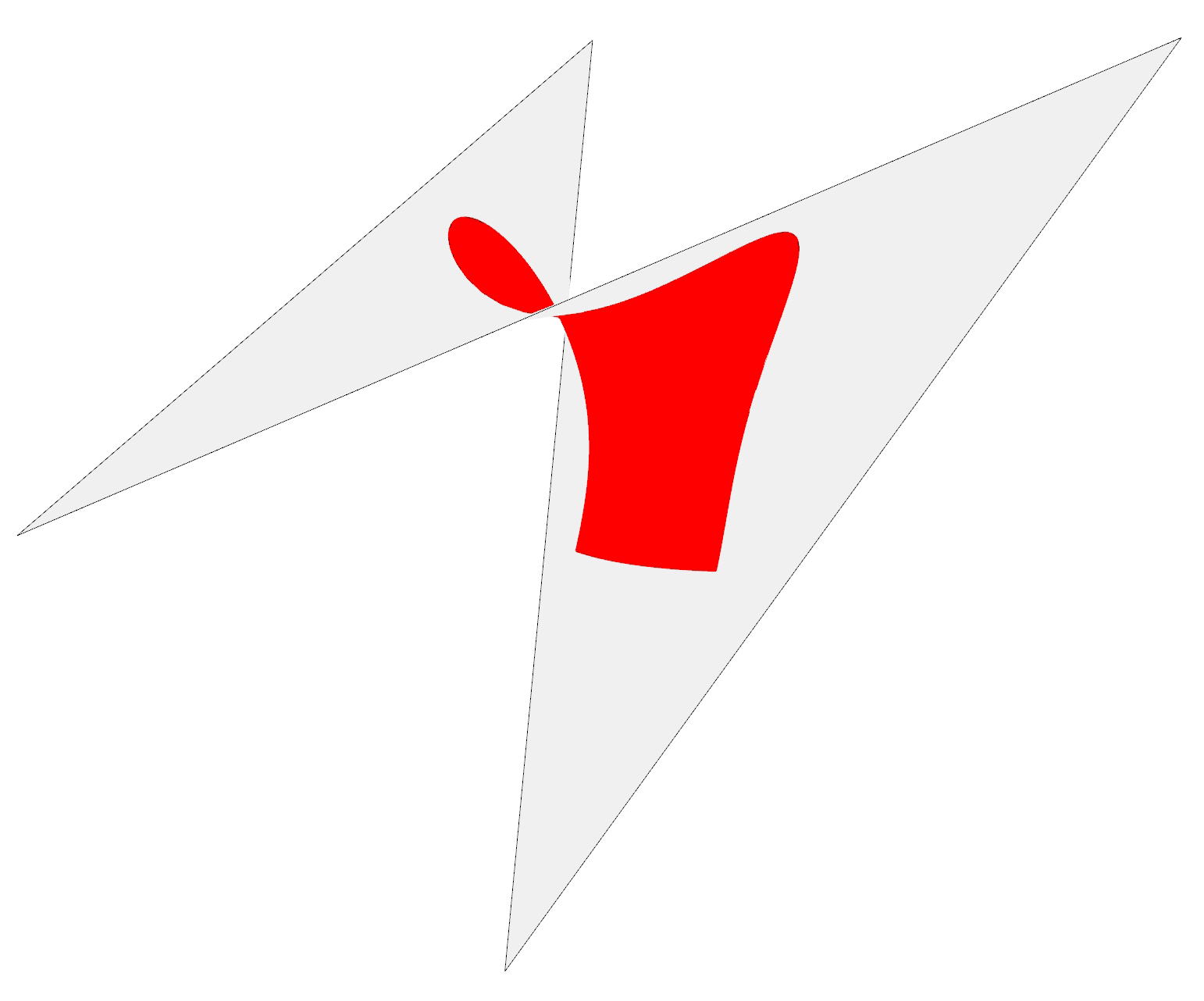

The Abri design is interesting on multiple scales. Most prominently, it provides passengers with shelter from the rain whilst being recognizable, inviting and transparent. It’s arching shape, with a free span of 3.5m and cover for up to eight passengers, combines a feeling of security with a wide view of the bay.

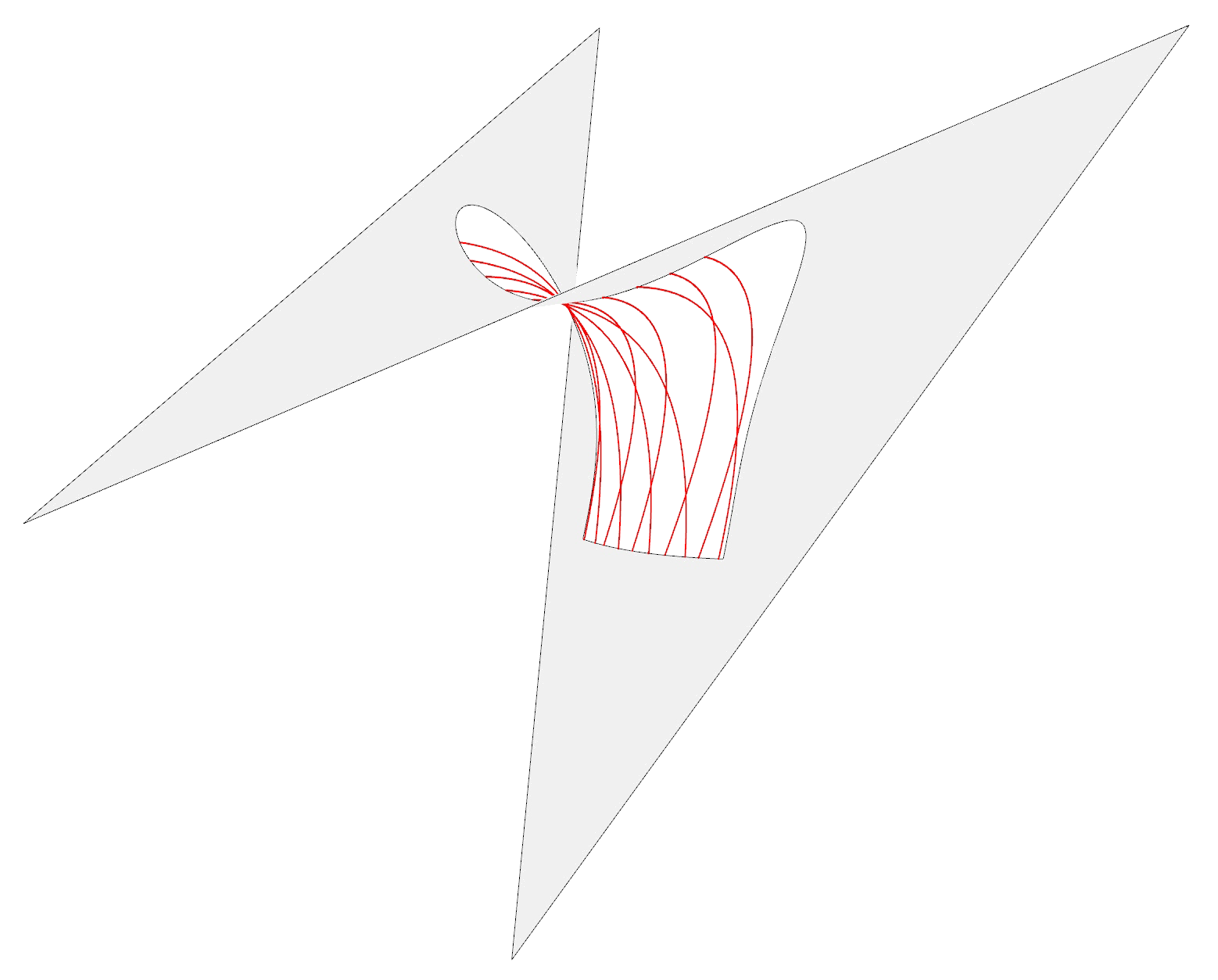

It’s elegant shape remains captivating at closer inspection by the diamond-shaped cushions that follow from the intersecting structural members. At the smallest scale intricate printing patterns convey a distinct feel of digital craftsmanship. Being a rule-based design, the Abri allows these three layers of design to be customized without losing production efficiency or structural performance.

The abri pushes current concrete printing technology to its limits. The shell consists of two intersecting surfaces that, by weaving in and out, create tunnels for threaded post-tensioning bars. Because of these the unreinforced concrete can create an impressive cantilever. The bars string the three prefabricated parts together and connect them to the foundation. The tension that results at the curved outer edge of the abri is introduced into the concrete surfaces using 24 unique mounting plates.

Cutting-edge production it´s main shape is constructed using concrete printing technology, developed in a collaboration between RAP and concrete manufacturer Bruil. This technology allows for large variations in shape, texture and pattern on a per-item basis without additional cost.

The cantilever benefits from the newly acquired ability to print slopes up to 25 degrees. The unique steel parts are printed using WAAM (Wire Arc Added Manufacturing) technology. Pilot at Marconistraat, Rotterdam With 40 locations scattered across Rotterdam’s riverbanks, the parametric design allows for unique stops to be generated within the same design space and manufactured with equal ease. The first Abri will be built on the Marconistraat in Rotterdam and will serve as an inspiring element within the newly developed Merwe-Vierhaven district.